LVDT Use in Weighing Systems

LVDT’s are frequently used to measure spring deformation in weighing systems and force measuring transducers (load cells). The displacement measurement and the characteristics of the spring (force/unit displacement) are used to calculate the applied force.

A simple weighing system like the one illustrated below will consist of a weighing pan, displacement sensor, coil springs, and a base.

Both the LVDT and springs are attached to the base, with the core assembly connected to the weighing pan. Alignment of the core assembly is precise enough to assure that no rubbing between the core and transducer ID takes place. The weighing pan is centered over the LVDT, and mounted on the springs. Once the system is constructed, the output of the transducer is mechanically or electrically zeroed. Placing an object on the weighing pan and measuring the displacement allows for the calculation of weight or force. To determine this value, the system simply multiplies the displacement (inches) by the spring constant (Pounds/Inch or Newtons/Inch). If the mass of the object is required, the gravity component (32 ft/sec.2 or 9.8 m/sec.2 ) must be factored out of the result.

More elaborate spring systems, such as multiple leaf springs or compound cantilevers, can be utilized to minimize temperature, reduce hysteresis effects, and improve linearity. The mechanical structures are designed to reduce the effects of side loading, vibration and other components of error.

Some form of damping can also be provided, particularly when measuring small weights. This type of weighing system can be used as a counter for objects of a known weight, such as coins or parts coming off an assembly line.

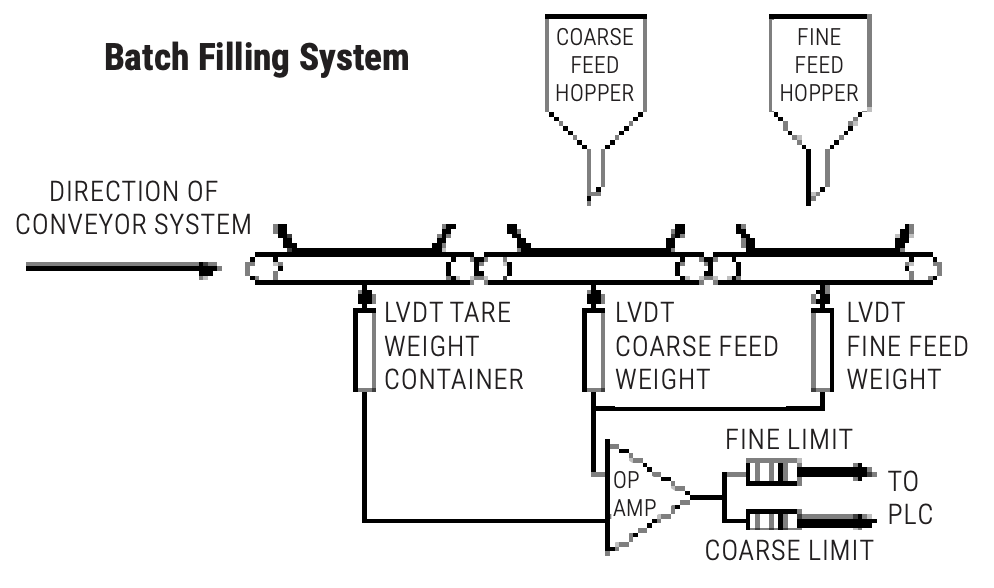

More sophisticated closed loop weighing systems are required for applications involving batching or mixing. The container and conveyer belt are first weighed so they can be factored out of the final measurement. The container is moved along a conveyor under a coarse and fine feed hopper. Under PLC control, a fast feeding mechanism quickly releases material from the coarse hopper and fills the container to a level slightly below the desired weight. A fine feeding mechanism brings the weight up to a final set point. Combinations of these systems can be used to produce mixtures of predetermined quantities of various ingredients. The illustration below is an example of such a system:

Other technologies commonly used as sensors in this application include strain gage, capacitive, resistive film, and ultrasonic transducers. LVDTs offer several advantages over these technologies, including ruggedness, life expectancy, and temperature stability.