LVDT Use in Specific Gravity Sensors

Engineers, as a means to create, often strive for the “least energy method” – or, in other words, the simplest way to accomplish a task. It is this concept that has led to the overwhelming popularity of the Trans-Tek DC-DC LVDT, represented by the Series 200 and Series 240. This accurate position feedback device is made convenient by complete signal conditioning electronics housed internally for DC-input/DC-output operation.

The DC-DC LVDT, or DCDT, is an integrated package consisting of a precision LVDT, a solid state oscillator and a passive demodulator. Powered with a regulated DC voltage, the oscillator converts this input to an AC voltage, exciting the primary winding of the LVDT. Voltages in the secondary coils are rectified and differenced in the demodulator. The resultant output is a DC voltage proportional to core displacement from the electrical center.

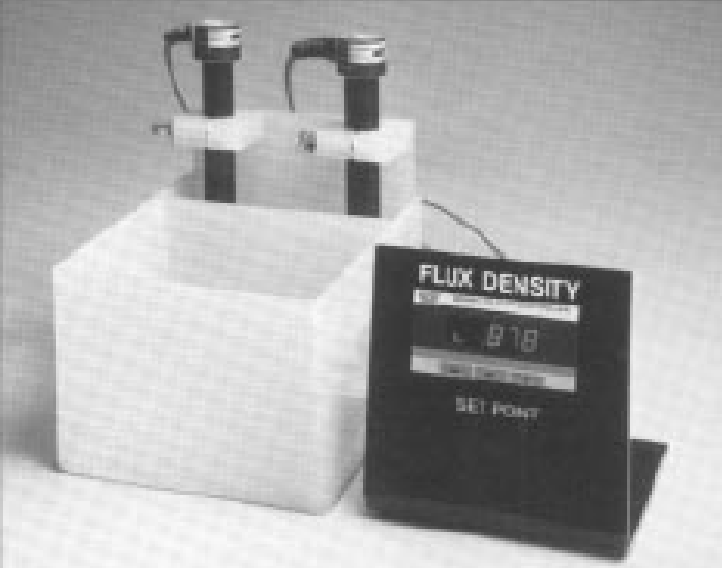

One original equipment manufacturer is making good use of this precision sensor. This manufacturer has developed a flux controller used in the process of machine soldering PC board assemblies. This system automatically measures and controls flux density through constant input from Specific Gravity and Temperature Probes in contact with the flux liquid.

Signals from the controller in turn activate pumps that add flux to maintain a selected set point. This system is likewise used for various other solvents and chemicals where fluid density is critical.

The Specific Gravity Probe suspends a float of known density into the flux liquid. While connected to a spring in the housing assembly, the float moves with the changing fluid density, thereby causing a deflection in the spring. In series with the spring is the Trans-Tek Model 0240-00153 DC-DC LVDT, a modified version of the 0240-00000 which includes an enlarged inner diameter bore of 0.155” versus the standard 0.125”. This feature is required to avoid contact between the core element and the transducer ID, thus eliminating any friction component. The signal output from the LVDT, when combined with the known values of the float and spring, is used to constantly monitor the density of the flux or solvent.

This application is also an excellent example of Trans-Tek’s flexibility in meeting customers’ demands. Because of the unique construction of the Gravity Probe housing, it is necessary that each of the four lead wires exit the transducer approximately 90 degrees apart. A special fixture was then incorporated in the production process to space the leads according to their requirements.

The DC-in/DC-out transducer is a compact and cost-effective means of measuring displacement. It is this convenience that attracts designers, technicians, and others to utilize this device in their wide-ranging applications.