Size of DC-DC Gaging Critical to Gear Tester

The Trans-Tek Models 0350-0010 and 0351-0006 DC-DC Gaging Transducers, found in the Series 350 family of LVDTs, offer an interesting alternative to the conventional spring-loaded LVDT. Each unit consists of full supporting electronics contained in a separate package wired six feet from the gaging mechanism. Isolating the electronics in this fashion leaves the gaging head with an excellent length to stroke ratio and only a 3/8” housing diameter, allowing for installation in tight areas.

With strokes of ±.050” and ±.010” respectively, the Models 0350-0010 and 0351-0006 combine the size advantage of an AC LVDT with the convenience of complete signal conditioning for DCin/DC-out operation. The electronics are neatly packaged in an MS Style connector housing and wired by a 6 ft. cable to the spring-loaded gaging mechanism.

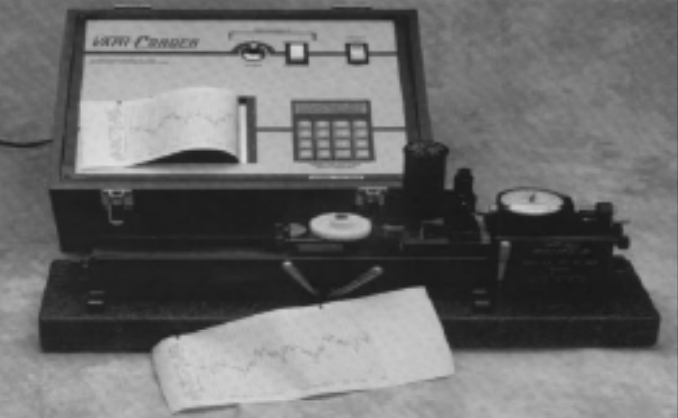

A leading manufacturer of high precision gaging equipment for the gear inspection industry has chosen the Series 350 Gaging transducers for their flagship product, VARI-ROLL Gear Tester. The VARI-ROLL Gear Tester uses a “building block” approach to gear inspection. System procurement can be economically tailored to fixtures needed for specific types and sizes of gears. The VARI-ROLL has proven that fine pitch gears and many coarse pitch ones can be composite tested both accurately and cost-effectively. This device has been actively used since 1952 by gear manufacturers and end-users in industries such as aerospace, automotive aftermarket, home appliance, government, computer and power tool companies.

The Model 0350-0010 is used to provide continuous position feedback on the VARI-ROLL. While the gear tester’s gaging head makes measurements on various gear styles, the LVDT accurately monitors dimensions looking for run-out or tooth-to-tooth errors. These values are checked against a master gear. The signal output of the transducer is an integral component of the electronic control loop, passing through an analog-to-digital card and onto a higher-level computer.

As a special recording option, the LVDT signal output is often coupled electronically to the VARI-CORDER which transcribes the linear movement of the VARIROLL headstock to a 100mm wide graph. Strip charts are produced by a digital dot matrix marking bar on heat-sensitive paper. As the LVDT looks for measurement errors in the gear, a line is drawn by the recorder verifying that each tooth falls within acceptable limits. These graphs serve as excellent permanent records for final inspection, troubleshooting and filing.

With the VARI-ROLL often used for finite measurement on fine pitch gears, the available space for adding features is minimal on this device. As our customers have discovered, the miniature size of the Models 0350-0010 and 0351-0006 accommodates strict packaging requirements, all made possible by the remote electronics.