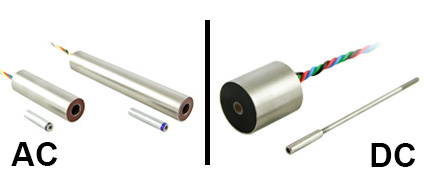

Should Your LVDT be AC or DC?

Written by transtek_admin on 08/31/2022

All LVDTs, regardless if they are AC or DC, have an AC operated core. Historically, AC was a sufficient output for earlier controls and instruments. However, as technology evolves, the demand for DC units continues to increase. Ironically, there is a shift back to using AC due to the several benefits it offers. Today we’ll take a closer look at the technology, a bit of history, and get a better understanding of why AC may be back in fashion.

Things Were Simpler Then

Earlier controls and interfaces were less demanding than today’s hi-tech counterparts. There were no PLCs. Users were not plugging sensors into laptops. AC provided the right power for the earlier generation controls and instruments used at the time.

The Rise of DC

Even today, a true AC position sensor does not have any internal electronics. However, in order to operate, it requires a carrier amp, oscillator, or demodulators and filters. As mentioned earlier, a DC unit has an AC-operate core, in addition to a carrier generator/signal conditioning component.

The desire for DC has grown over the years, driven by increased implementation of newer digital control and output technologies. Besides the AC core, a DC system includes modules that convert AC to DC. By using the device’s existing power, say 12v or 24v, they can plug it into a PLC, computer, control circuit, etc.

Benefits of an AC LVDT

Recently, newer engineers are again implementing AC-only designs due to the many benefits, such as:

- An AC LVDT is a simple device overall: it’s just windings with a magnetic core

- Less expensive

- No electronics/control circuits, which helps save space

- Much more rugged overall. Can withstand higher temperatures and pressure. They are submersible in non-conductive fluids, without the need for sealing. (If submerging in water, the windings would need to be sealed.)

- Can be put in applications where electronics wouldn’t hold up, including hazardous areas.

- Withstands shock and vibration, unlike electronics which, despite being solid state, don’t hold up well

- Better frequency response. You get the output quicker.

- You can generally run the wires out farther with AC than with DC

While the list of pros is long, there are relatively few cons. But they could be potential deal breakers for certain applications.

- AC can be tougher to use. Remember, at some point you have to interface with a display or control. Most of these are DC. If you are strictly staying with AC, you may need to design your own circuit. With DC, you can utilize commonly available components.

- If you need DC, you’ll need a signal conditioner to convert it. This generally slows things down. This might be an issue, but it depends on what you are measuring.

AC vs DC LVDTs: Who Wins?

So what will it be? AC or DC? As you can see, it all depends on the application and the amount of resources available. An AC system, thanks to its simplicity, does offer a great deal of benefits. However, those alone will not be the deciding factors. You must consider all parts of the system such as controls and displays, and how they will be powered. This is in addition to the LVDTs application requirements and environmental conditions. Choose wisely!