LVDTs vs Alternative Methods For Thickness Measurement

Written by transtek_admin on 02/24/2025

For thickness measurement, manufacturers have a number of options: optical, capacitive, inductive, and contact-based methods. Each has its own strengths and drawbacks. The ideal choice depends on the demands of each use. Let’s see how LVDTs measure up when compared to some alternatives for a few interesting applications.

Precision and Environmental Tolerance

Generally speaking, LVDTs have been known for their precision and flexibility with relatively simple operations. They thrive in industrial environments where most measurement technologies can’t. Unlike optical systems that cannot perform well under dirty conditions or other extremely harsh settings, an LVDT often works best. Specific examples include the following:

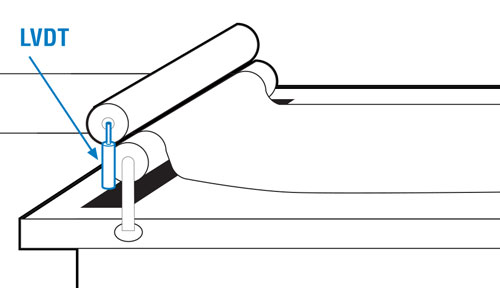

Cash Dispensing from ATMs – Accurate measurement of bill thickness is important in automated teller machines for the right cash handling. Either LVDTs or optical sensors are used to ensure that the each bill falls within a specified thickness tolerance to avoid multiple bills being dispensed at once or causing a machine jam. By monitoring the exact thickness of the currency, these sensors ensure that accurate bill dispensing occurs, which is critical to transaction reliability and mechanical failure prevention. Historically, LVDTs have been used thanks to their accuracy and reliability. However, space limitations demand smaller solutions. Since this a relatively clean process, optical sensors may be used as well since they are more compact. However, they could come with higher price tags depending on the exact technology used.

This LVDT measures bill thickness as it moves through the ATM

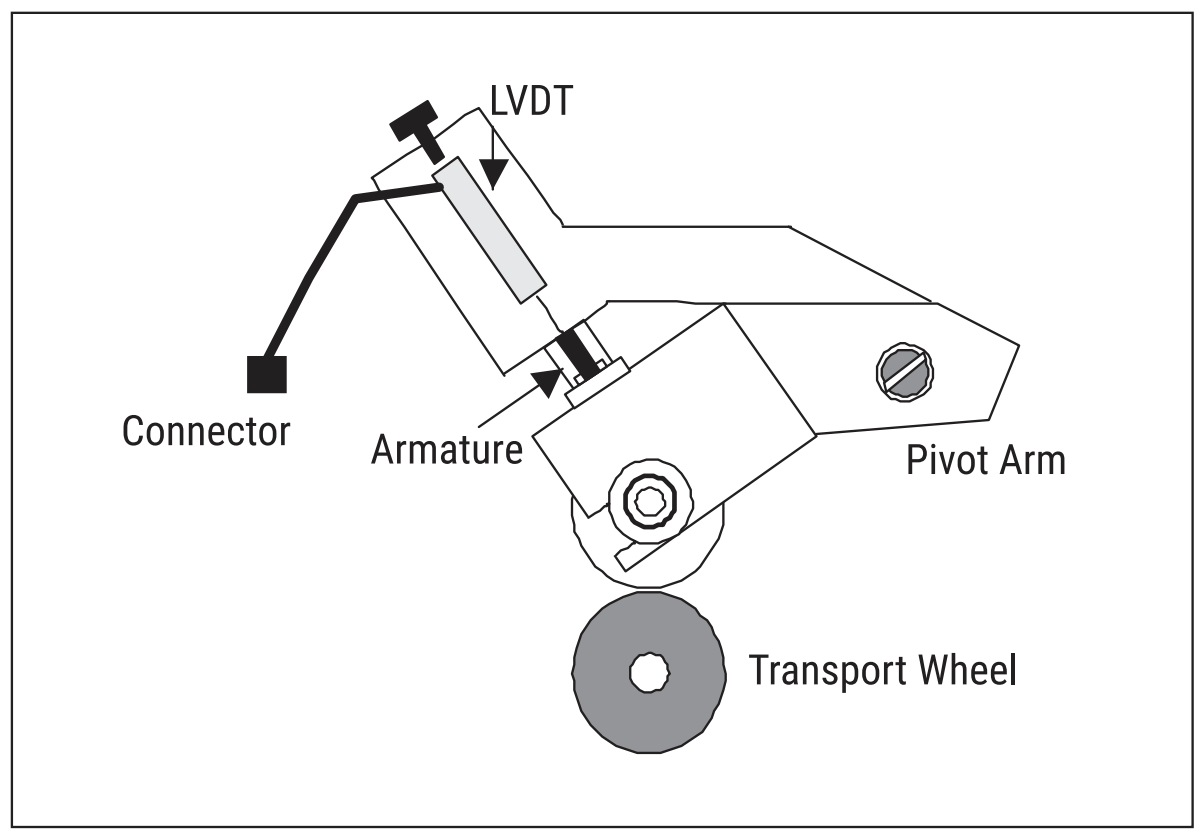

Plastic and Composite Manufacturing – During production of plastic and composite materials, consistent thickness is required for product quality. For example, if a plastic sheet becomes too thin, it may not possess the required strength for its intended application and may turn fragile or tear easily. The material can either be tested on the line or checked separately. Inductive sensors, due to the operating principle, wouldn’t be able to sense it. While a capacitive approach would be overkill, they are more expensive and exceed the requirements of the task.

Typically, LVDTs are employed for material thickness monitoring as the material emerges from molding machines, detecting variations that might cause a compromise in structural integrity. By providing real-time thickness measurements, LVDTs enable the manufacturer to maintain strict quality control, ensuring each product meets precise dimensional specifications. If a specific thickness is not required but there is a target minimum, a feeler or clicker type sensor could be used to determine if the material reaches a minimum thickness.

Industrial Component Monitoring – During machine die and stamping operations, the incremental wear and erosion of critical components must be measured. As mechanical parts are subjected repeatedly to stress and friction, their dimensions change gradually. By continuously monitoring thickness variations, potential equipment failure can be predicted before it occurs. This predictive maintenance approach allows manufacturers to schedule replacements or repairs proactively, minimizing unexpected downtime and reducing overall maintenance costs. While a few approaches could be employed for this use, LVDTs are generally the method of choice due to their extreme accuracy, budget friendliness, and functional ranges.

Core Sampling and Drilling – These are among the most challenging tasks in demanding environments, such as geological explorations and fracking, where thickness and compression must be measured. During core sampling, sensors monitor the deformation of materials under very high pressures and temperatures.

Measuring subtle thickness changes in a sample during drilling or compression tests provides geologists and engineers with vital data on material properties, structural integrity, and potential complications arising during resource extraction. Given the intense pressure and temperatures of that application, LVDTs utilized are usually ruggedized versions of the standard units. Most other alternatives just can’t stand the extreme demands of this application.

Razor Blade Manufacturing – For this application, thickness measurements are necessary to ensure the correct amount of blades is loaded into the cartridge. It’s a messy environment, though, as blades are coated in oil and debris. Optical or capacitive sensors would struggle as they would be quickly contaminated. Inductive sensors could to the job since they are compact and are protected from contamination, but they do get pricey. Due to their ruggedized nature and relative cost, LVDTs are a good choice. They will perform accurately and consistently, ensuring precise quality control.

Technology Comparison

Here’s a quick summary of each approach to thickness measurement:

Optical Systems – Precise but sensitive to environmental conditions

Capacitive Sensors – Extremely precise for applications such thin films but often overengineered for general applications

Inductive Sensors – Excel at working with metal objects in non-contact situations, but otherwise limited by material conductivity and can be more expensive

LVDTs – Versatile, reliable, and often the most cost-effective solution

When to Choose LVDTs

LVDTs are particularly advantageous when:

- The environment is dirty or harsh

- You need non-contact measurement

- Cost-effectiveness is a priority

- Measurement involves moving or changing materials

For manufacturers seeking a reliable, adaptable thickness measurement solution, LVDTs offer an impressive combination of precision, durability, and versatility. Their ability to perform in diverse industrial settings makes them a go-to technology for quality control and process monitoring.

When it comes to precision measurement, the choice of the right technology makes all the difference. Linear Variable Differential Transformers have emerged as robust and versatile solutions for thickness measurement in several industrial applications, offering unique advantages that set them apart from alternative technologies. However, the optimal solution depends on the operational environment, budget and other factors that will change from use to use.