Applications for Gaging Linear Variable Displacement Transducers (LVDTs)

Written by transtek_admin on 01/31/2023

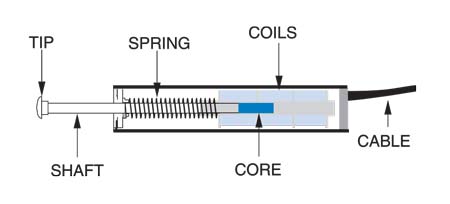

Gaging Linear Variable Displacement Transducers (LVDTs) are used to provide accurate linear displacement measurements for any application that requires a spring-loaded transducer. This alternative design and construction approach is required since a conventional free-unguided LVDT doesn’t always fit the bill. Specifically, they can’t be used where the moving object can’t support a direct connection to the core assembly of an LVDT.

Gaging transducers, also known as spring-loaded LVDTs, rely on high-quality springs to perform accurate and consistent measurements, along with a shaft containment and guidance mechanism. The spring type will vary depending on the specific use, but fall into two general categories: conical and compression springs. Conical springs have a smaller compression height, while compression springs have a larger one. These springs are typically made from either stainless steel or music wire.

Applications for gaging LVDTs vary greatly. They are used in a variety of manufacturing processes, typically for part inspection. They are also utilized to measure or monitor a range of conditions outside a factory. One extreme example would be the use of our gaging LVDTs to monitor the stability of Mt. Rushmore! The purpose of these sensors is to monitor the movement of the rocks, and trigger an alarm as needed. While we love to share that story, let’s take a look at some of the more popular uses:

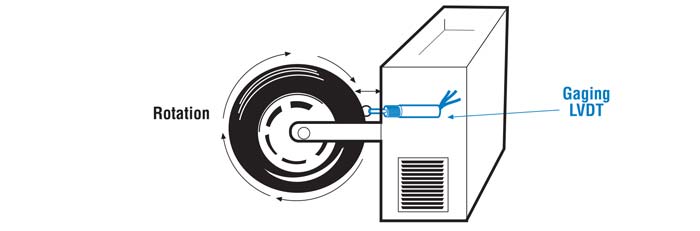

Rubber Tire Runout

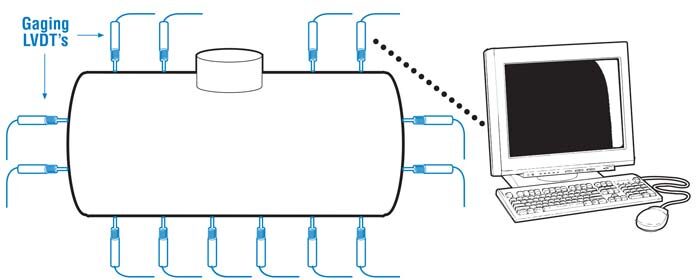

Tank Expansion Measurement

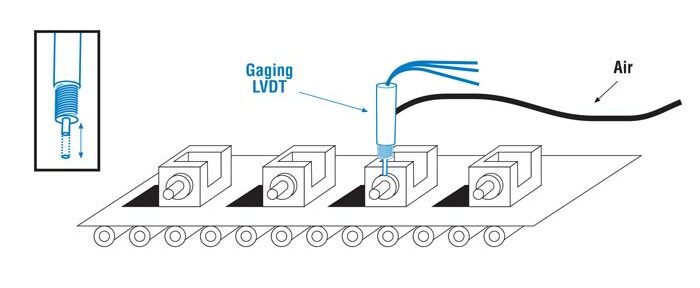

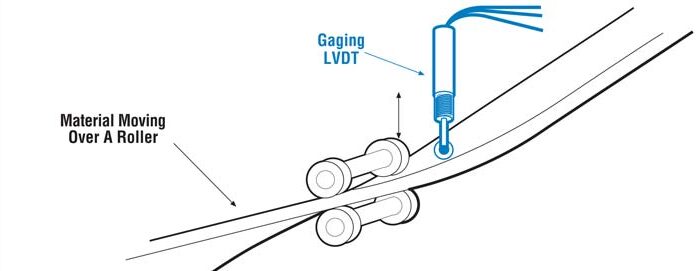

Material Thickness Measurement

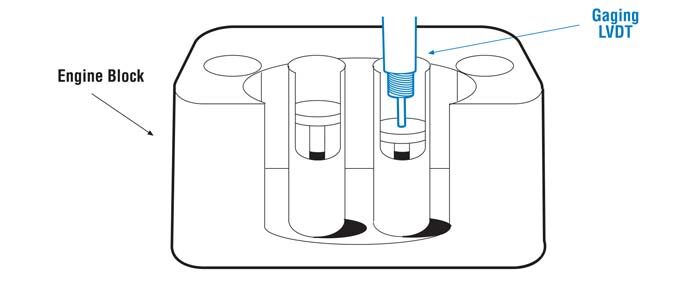

Cylinder Head Valve Testing

Part Inspection