Miniature Gaging for Manufacturing Machinery Improvements

Trans-Tek has addressed the ongoing need for precision linear feedback in a compact design with two transducer groups: the Series 230 and Series 330 AC-AC LVDT. Featuring a 3/8” diameter housing with excellent stroke to length ratio, these sensors are growing in popularity because of their superior measurement ability and miniature size. While having the same available working ranges and electrical parameters, the Series 230 and Series 330 differ only in their mechanical configurations.

The Series 230 AC LVDT contains an ID hole through the center of the transducer’s coil form where a ferromagnetic core travels linearly to provide a continuous electrical feedback. Attached to a nonmagnetic extension rod, this free-floating core must be guided within this opening, as well as pushed and pulled through the entire working range of the transducer.

For the Series 330 AC Gaging LVDT, a similar core and extension rod pass through the center of the transducer, terminating outside the housing as a .125” shaft with removable tip. This assembly is captive-guided by a linear bearing and spring, which keeps the shaft fully extended in its normal resting position. Measurements are taken by compressing the shaft, which in turn pushes the core through the internal coil form. Releasing the shaft allows the force of the spring to return it to its fully extended position.

One customer making great use of both the Series 230 and Series 330 Transducers is Mid-West Automation Systems (MWAS), Buffalo Grove, IL, a division of DT Industries Automation Group. Working closely with each client to solve specific production problems, MWAS specializes in the design, manufacturing and integration of custom precision assembly systems. Overseeing each project from concept to completion and assuming full machine design responsibilities, the final result is always an improved manufacturing process and higher efficiencies.

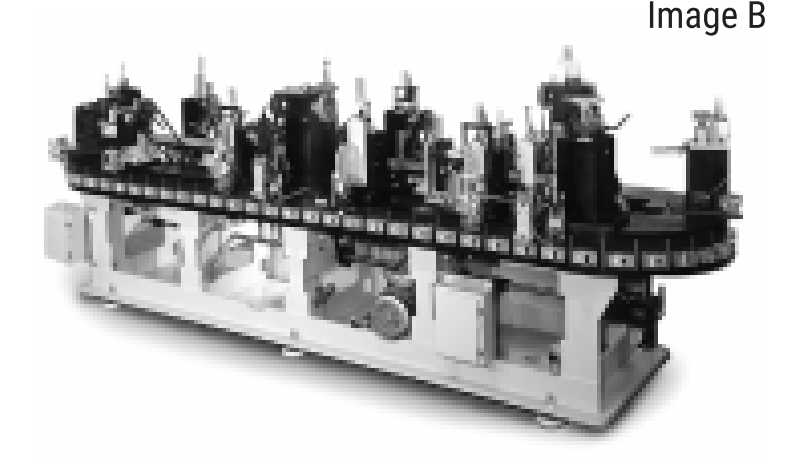

Two specific examples of automation equipment developed by MWAS are the Inline (Image A) and Carousel Conveyance Systems (Image B). Both items feature high cycle rates and a standard base platform to build upon for particular assembly needs. Incremental lengths can be added and deleted in sections and the modular design allows the configuration to be changed using standard pick and motion control devices.

MWAS has used the Trans-Tek Model 0332-0000 AC Gaging LVDT, with its ±0.025” working range, for similar automation systems. As with most applications involving part inspection, the transducer is lowered until the tip makes contact with the manufactured product passing on a conveyor. A measurement is taken, with the LVDT signal routed through an analog card and onboard logic control instrumentation. The measured height of the component is checked against a preset specification and tolerances. The production process continues with defective parts being separated from acceptable ones.

For automation equipment needing very specific spring loading characteristics, MWAS has modified the Model 0232-0000 AC LVDT to include their own specially designed spring assembly external to the transducer. This add-on is simply done by attaching extension rods to both ends of the core and extending them out through the openings of the LVDT ID hole. At the lead-end, one rod is fastened using a nut and washer. The same is done at the opposite end, except with a spring sandwiched between the nut and washer and base of the transducer. In the end, the goal is to duplicate the gaging mechanism of the 0332-0000, allowing for minimal contact while carefully inspecting the finished product.

With packaging almost always a design issue, these miniaturized transducers enable the end-user to obtain accurate linear readings in a compact space.