LVDT Use in Robotic Manipulator

The Trans-Tek Series 240 DC-DC LVDT, available in strokes ranging from ±0.05” to ±3.0”, is an accurate position sensing transducer complete with internal supporting electronics. Driven by a regulated power supply between 6 and 30 VDC, this transducer provides a linear DC voltage output over its working range, with a standard ±0.5% maximum non-linearity of full stroke.

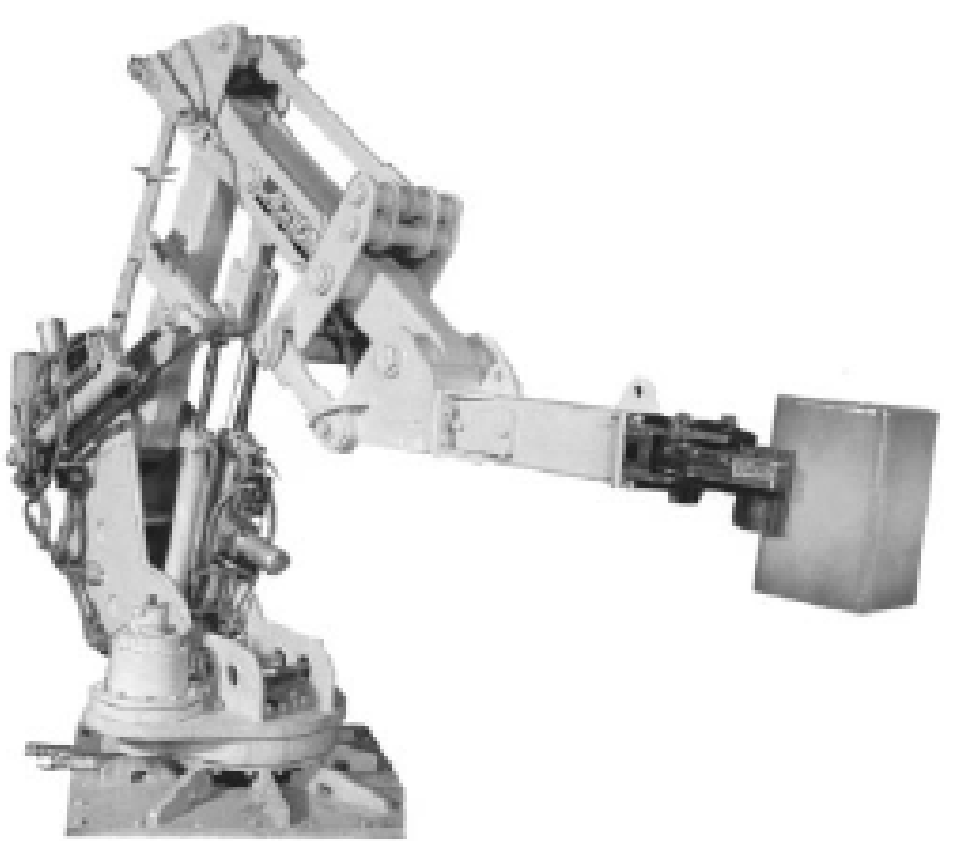

A leading manufacturer of industrial manipulators has selected our Series 240 DC LVDTs for use in their product. These manipulators are used in severe-duty applications – where heat, dust, and vibration are the norm. These rugged, long-reach machines are often found in the forge, foundry and casting industries. Controlled by an operator or by the program, the machines allow precise handling of complex, repetitive motions with large payloads of up to 7000 kg and reaches to 10 meters. Hazardous materials often handled include hot billets, large molds, ingots, waste and much more.

There are four levels of control available for these machines: simple levers, joystick, a master-slave pantograph, or full robotic control. The controls must be able to move the custom tooling located at the end of the boom in 3 Axes: Yaw, Pitch, and Roll. The simple levers and joystick control will give an operator visible results. This is the least automated control system, similar to the hydraulic controls found on most booms. Taking this manual control one step further, Action has developed a master-slave Pantograph operation using three Trans-Tek Model 0244-00000 DC-DC LVDTs to sense an operator’s arm movement.

The operator sits in a cab that is attached to the manipulator, and places his arm in a carefully constructed control center. The precise pantograph control directs the manipulator arm to follow the operator’s arm motion. The output signals from the three LVDTs are fed directly into the onboard electronics and is the main component in the continuous feedback loop controlling the robotic arm. Special load sensing lets the operator “feel” the motion in critical movements such as picking, placing, dipping, or hanging large payloads.

Complete robotic control is the last step in fully automating this machine, and can provide over 4000 program steps for repetitive movements in volatile environments. The cost for one of these machines starts at around $300,000, with the majority being sold overseas. Our customers have discovered the convenience, reliability, and cost-effectiveness of the Series 240 DC-DC LVDT. With a precision LVDT and complete signal conditioning electronics nicely packaged in one unit, it is no wonder this style transducer is Trans-Tek’s best selling product.