LVDT Use in ATM to Sense Dollar Bills

Miniature transducers, such as the Series 230 AC-AC LVDT, offer high accuracy linear measurement in a compact design. Packaged in a 3/8” diameter housing with excellent stroke to length ratio, these units are often utilized where size constraints prohibit the use of standard LVDT’s. In addition, the low-mass core is ideal for systems with low driving forces or high acceleration and, therefore, will not adversely influence the delicate nature of these applications. Operating ranges are available from ±0.005” to ±1.00”, divided into eight intermediate strokes.

Despite their small size, the models from the Series 230 are rugged sensors, making them well suited for a wide variety of industrial applications. Where changes in position are a small percentage of the total stroke, the end-user benefits from this item’s infinite resolution and superb temperature stability. If any of the Series 230 units are overranged, system reversal is avoided with monotonicity maintained at 150% of the normal working range. (Monotonicity is defined as continually increasing or decreasing output signal.)

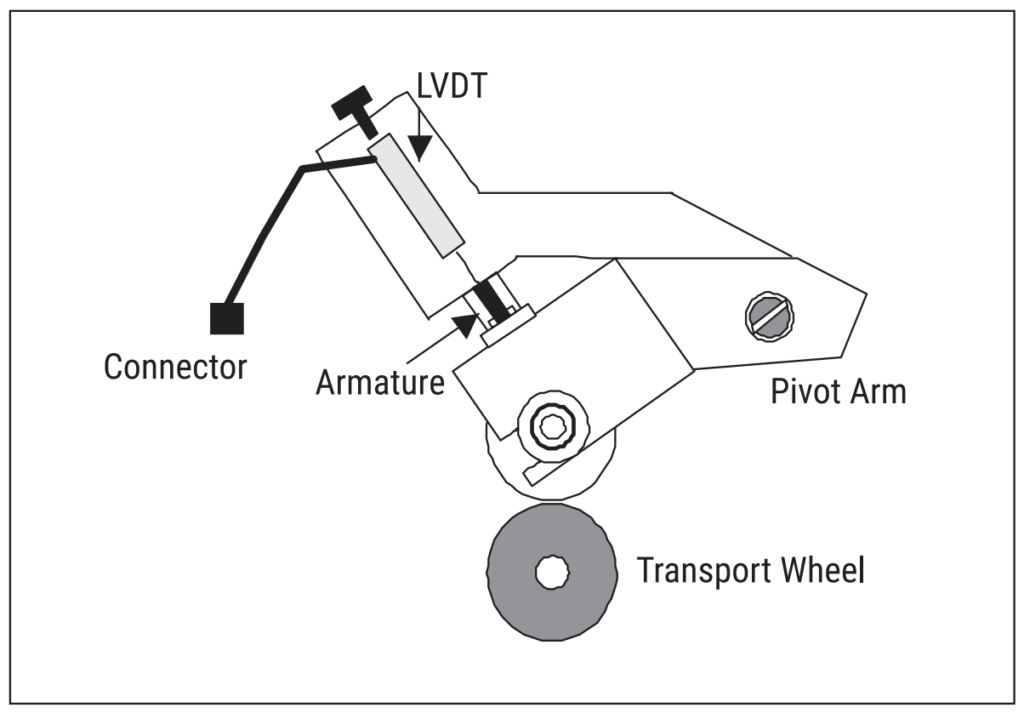

One application requiring a miniature LVDT is the multiple bill detector of an automated teller machine, or ATM. This mechanism is capable of detecting single, double and triple bills, as well as folded, taped, overlapping and soiled bills. The LVDT assembly is carried on a block fixture fastened between the structure’s side frames. A shaft attached to the block acts as a pivot point for two support arms. A small diameter metal wheel is mounted at the end of each arm. Springs apply constant pressure so that each wheel bears down on the top of a larger diameter wheel, which is attached to a gear-driven shaft in the transport. Bills passing between the two sets of wheels push up on the small wheels. This motion is transferred to the LVDT core element through an armature stationed above the pivot arm, thus generating a changing output signal. As the bills pass between the rollers, the voltages vary according to the thickness of the bills.

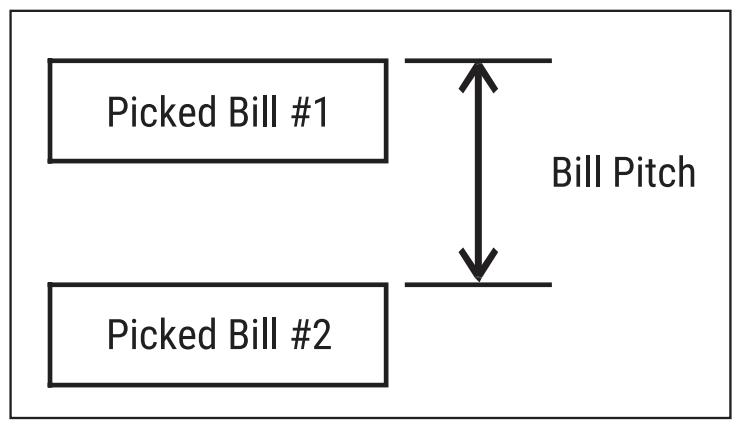

To account for any eccentricity of the rollers or dirt accumulation on the roller surfaces, a sample reading is made for one complete revolution. This function is performed before bills are picked at the start of the dispense operation. Total roller movement is equivalent to one bill pitch.

Voltage readings are taken alternately from each LVDT, measuring each interrupt from the main timing disk. (This timing disk also determines when one total revolution has been completed.) The overall sample reading is obtained by integrating varying LVDT outputs for one bill pitch. This value is stored electronically and is later subtracted from the reading of an actual bill passing through the roller wheels. The resultant number represents the crosssectional area of the bill and is immediately compared to an existing table of cross-sectional areas for single, double and triple bills. This mathematical process eliminates the risk of passing an unexpected number of bills, while at the same time compensates for the buildup of debris or dirt on the roller surfaces.

A common goal for most designers today is to incorporate precision sensors with the smallest possible package. With increasing emphasis placed on size constraints, the Trans-Tek Series 230 transducers are a great alternative for position control in areas of limited space.