Trans‑Tek calibrates 100% of its transducers before shipment. Linear Velocity transducers come with a strip chart recording of the output which details important parameters such as sensitivity and stroke length. All Linear and Angular Displacement Transducers come with a computer-generated calibration report. In this calibration report, we list measured and calculated parameters such as sensitivity, calibration input voltage, and non-linearity. To calculate non-linearity, we must compare the actual data against a theoretical ideal. Trans‑Tek uses three methods to calculate the ideal comparison line: Zero Base – Average Terminal, Best Fit Straight Line, and Best Fit Straight Line Through Zero. Each calculation method is described for you below.

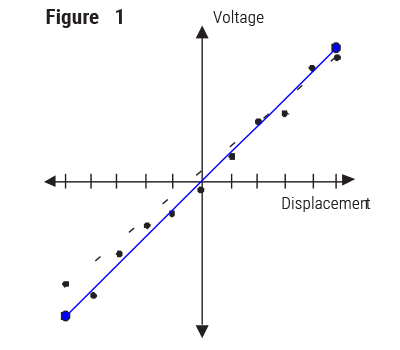

Zero Base – Average Terminal

This is one of the first methods Trans-Tek used to generate ideal data. It is also simple enough to be calculated manually, without the assistance of computers. Data is taken from the transducer over the desired measurement range. This data is represented by the black dots in the chart pictured in Figure 1. In order to force the line between the measured endpoints through zero, a new line is generated by taking the average value of the existing endpoints. This new line is represented in blue. Each data point is then compared against this line, and the non-linearity computed.

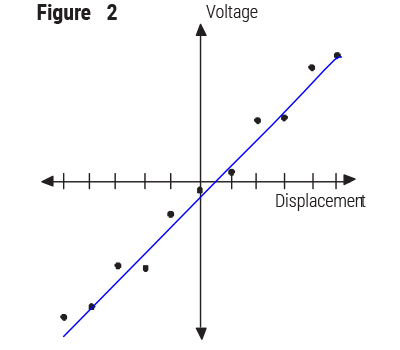

Best Fit Straight Line

The Best Fit Straight Line method of calculation is represented by Figure 2. This calculation method is calculation intensive, and for practical purposes requires the use of a computer to analyze the data. Data taken from a transducer is analyzed numerically to produce a line resulting in the smallest non-linearity at any given point in the line.

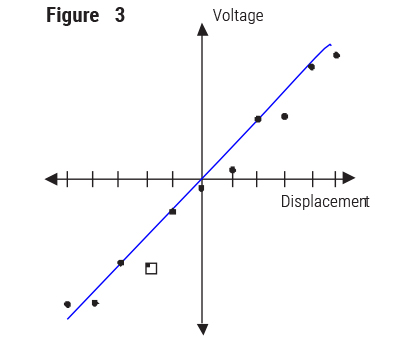

Best Fit Straight Line Through Zero

Calculating an ideal line using this method requires that the line have a Y-Intercept of Zero. In order to make it “Best Fit”, the slope of the line is adjusted around the zero point until the resulting non-linearity at each point is at its lowest value. This method is represented in

Figure 3 below.

All of these methods are valid representations of an ideal line to which we can compare measured data. Knowing the method by which the line is computed will enable users to effectively duplicate the process.