LVDT Use in Servo Valve Displacement Sensing

There is a growing interest in the use of LVDT’s to provide position feedback for electrohydraulic proportional valves, a direct result of the enhanced performance that is realized when LVDT’s are utilized for process control.

Mounted on the hydraulic valve, the LVDT contacts the spool to provide an electrical signal corresponding to spool position. The valve’s electronics compares this signal to the desired spool position. The result is a closed inner-loop system that continuously monitors and corrects the spool position. The benefits that are experienced from this application include increased frequency response and reduced hysteresis effects of the control valve.

The customer has a few options in terms of how the LVDT can be installed in the hydraulic valve. In each case, pressurized hydraulic fluid is present in the valve and must be considered when incorporating the LVDT.

The traditional method involves passing our core assembly through a shaft seal and connecting it directly to the spool. This places the LVDT entirely in ambient pressure, protecting it from high pressures. Please see Figure A.

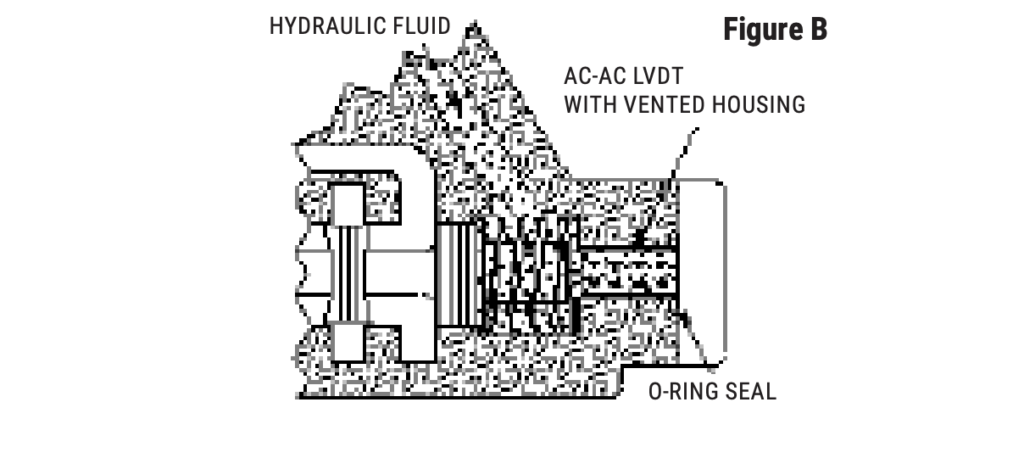

Many of our standard LVDT models also have a high-pressure version to allow for operation while immersed in hydraulic fluid at pressures up to 5000 PSI. This is achieved by venting the housing to allow for equal pressure inside and outside the unit, and changing internal materials to be compatible with hydraulic fluid. See Figure B.

A third possibility involves placing the LVDT core assembly inside an isolation tube to isolate the transducer from high pressures. Since the presence of the tube may affect such performance parameters as linearity and sensitivity, it is usually required that the tube specifications be considered through all stages of design and testing. Please see Figure C.

Trans-Tek has developed an AC-AC LVDT specifically designed for use in spool control valves. The Model 0291-00090 has a total working range of 0.200 in. and a linearity that far exceeds most customer requirements of .5%. Although not described in our standard catalog, this unit features an excellent stroke to length ratio and is low cost.

Trans-Tek control drawing, C012-0156, shows full specifications for the Model 0291-00090 and is available upon request. If you should require any additional information regarding this item or any of the topics discussed above, please contact the Trans-Tek Applications Department.