Low-Cost AC LVDTs Keep Things in Balance

The Series 280 AC-AC LVDTs represent our low-cost solution for linear position feedback. While this group provides the same stable readings and rugged construction as most LVDTs, other Trans-Tek AC lines offer better overall performance. For example, Linearity is specified as ±0.40% for the Series 280 and ±0.25% for the Series 210-220. This would suggest that the 210-220’s provide a much higher absolute accuracy and resolution than the 280’s.

But don’t try telling that to this innovative system designer that has developed a cutting-edge automotive crankshaft balancer using our Model 0280-0000 (±0.050”) to monitor very small displacements. The shaft is analyzed by spinning it and sending the recorded dynamics to a computer program. With their extraordinary efforts in designing signal conditioning for the LVDT, this customer has achieved resolutions of better than one-millionth of an inch. And taking such small measurements helps to make the best crankshaft possible.

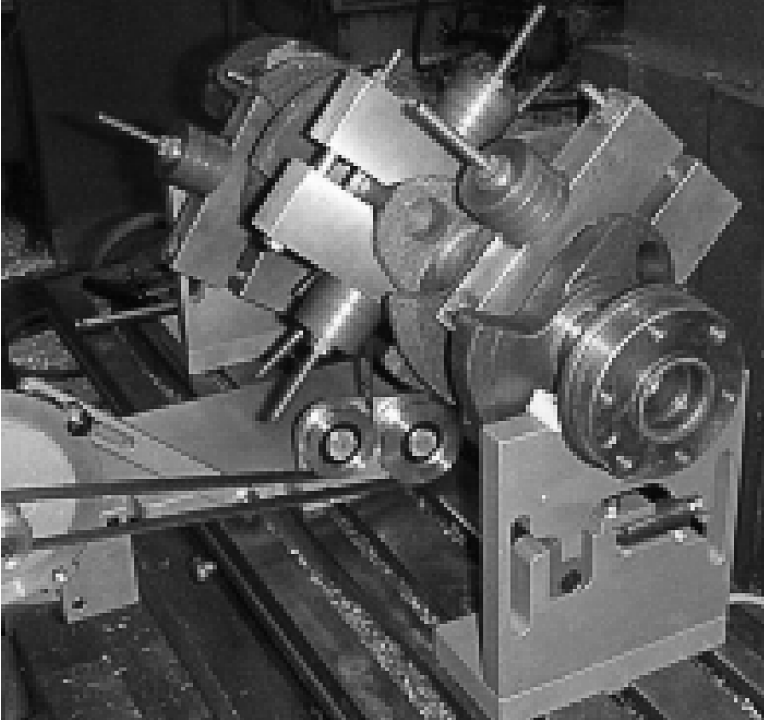

A Model 0280 is located on each end of the balancer,

mounted inside the cutout portion of two L-shaped brackets, or “uprights”, as seen in the photo above. At the top of each upright is a V-shaped cradle lined with Delrinâ plastic where the shaft is allowed to spin freely. Bobweights are attached to strategic points on the shaft to simulate the reciprocating motion of an engine’s pistons and rods. While the shaft is spun by a motor at 500 rpm, a constant vibration results in a linear movement, radial to the shaft. With the LVDT body hard-mounted to the base of each upright and the transducer’s core linked to the cradle holding the shaft, this side to side movement is detected by the LVDTs.

The readings from both LVDTs are converted from analog to digital and then fed into a software program that generates a best-fit sine wave curve. Force values are eventually calculated to determine exactly where and how much material to add or remove from the shaft.

Making the most of a situation, this customer has taken our economy-line AC-AC LVDTs and turned them into super‑precision devices. The capability is there – refining the supporting electronics is up to the end-user.