LVDT Use in Automotive Suspension

For OEM applications, AC-AC LVDT’s from the Series 270-280-290 provide cost-effective solutions for accurate position feedback. To fully support these transducers, only basic electronics are required, including one of several commercially available Integrated Chips or I/C’s. Combining an AC-AC LVDT with the necessary electrical components will result in a relatively low-cost system with high-end performance.

AimRite Holdings Corporation is a pioneer in the field of computer-controlled suspension technology for the automotive industry. Targeting mainly sports utility vehicles (SUV), trucks, buses, and RV’s, AimRite’s trademark product – the COAST system – uses the Model 0283-0000 AC-AC LVDT for continuous position feedback. This advanced suspension design offers numerous benefits including: luxury car ride with sports car performance, on-road and off-road application, replacement of sway bars and shock absorbers, simultaneous control of all vehicle dynamics, compatibility with conventional or air springs, reliability and flexibility at a minimal cost, and robust construction.

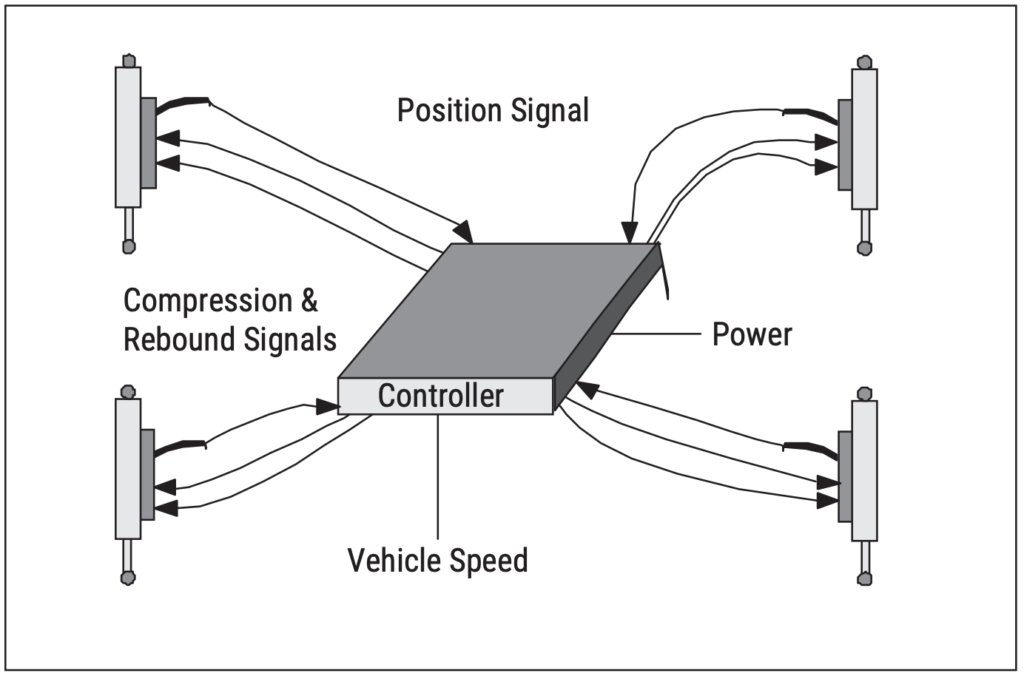

The COAST system consists of four electronically adjustable hydraulic control units for a standard automobile or SUV, all connected to a computer controller. Six units are required for a truck, bus, or RV. Each control unit contains its own LVDT which reports the exact position of each wheel in hundredths of an inch to the controller 200 times per second.

The controller then determines the optimum force needed for every wheel and sends this compensation factor to each unit, also at a rate of 200 times a second. Each control unit in turn generates the proper force, ranging from over ±1000 pounds for a standard automobile or SUV to over ±2500 pounds for a truck, bus, or RV.

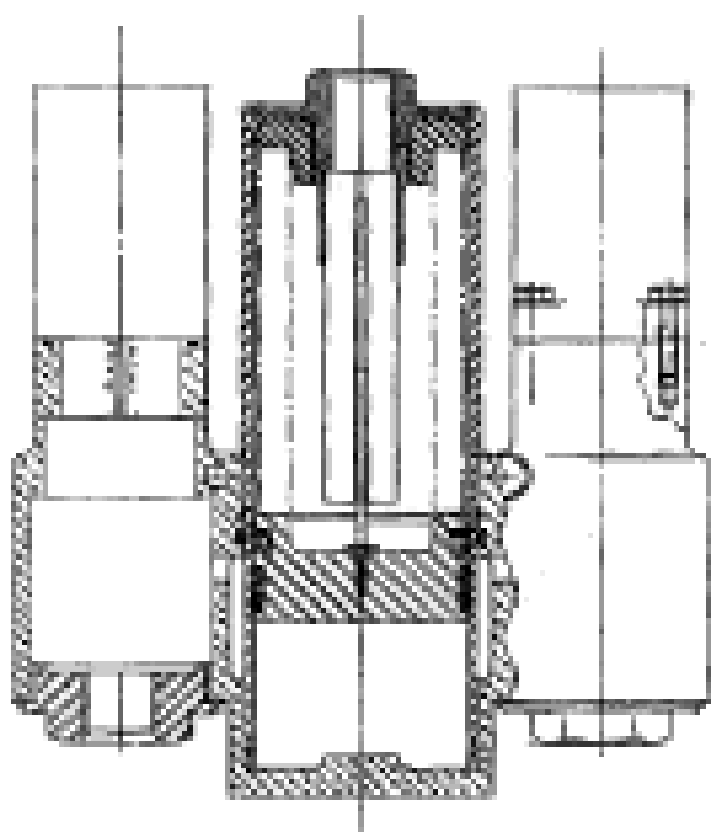

The COAST constant force approach differs from conventional damping in that it uses pressure regulators rather than orifices to control fluid flow. The LVDT measures the fluid level through the position of a float inside a valve. Housed in each hydraulic control unit, the valve reacts to the up and down motion of the wheel and the LVDT takes a precise reading of that movement. This design gives COAST a key technical advantage. An orifice must be constantly and very rapidly adjusted as the wheel moves, whereas the COAST system supplies a signal representing the appropriate force based on the fluid level change. The force value is largely independent of any movement at that instance of time.

The COAST system is totally automatic: continuously monitoring and controlling the vehicle’s ride performance to provide soft and stable ride characteristics. Its parameters can be configured to any specific land surface transportation vehicle. COAST adjusts and controls up to nine dynamic areas of a vehicle’s suspension through its unique and patented adaptive suspension technology. The position feedback signal from the LVDT is a critical source of data, processed by the computer controller to obtain independent control responses for each degree of motion.

AC-AC LVDTs provide a cost-effective solution to OEM applications requiring a rugged sensor with accurate and reliable position feedback capabilities.